Heater protection using float switches

Details

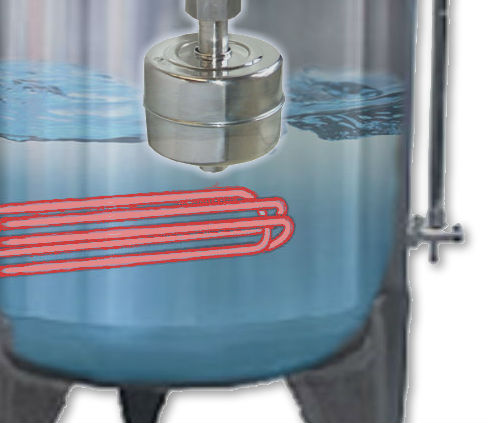

An immersion heater is used to heat a liquid to a specific temperature. The applications range from water, oil, chemical processing, and beyond. Controlling and maintaining temperatures in various applications is critical to many different industrial processes. Immersion heaters can be damaged or burn out if the liquid level is allowed to drop below the heating element. The heater should be turned off if this happens to prevent damage which can lead to dangerous situations. A float switch can be installed just above the heating element to prevent this from happening. When the float drops it can trigger a relay to cut power to the heater. Using a liquid level float switch can automate this process saving time and money.

Common Applications

- Food and beverage processing

- Chemical processing

- Hydraulic oil tanks

- Water heaters

- Freeze protection systems

How does it work…

A float switch is installed in the tank or vessel. They can be installed vertically or horizontally and are available in many different materials. The float should be positioned above the heating element. If the liquid level should drop below this point the float switch will trip a relay to automatically cut the power to the heater preventing costly damage or possibly dangerous conditions. When the liquid level is raised above the float switch, power will be restored and the heater will turn back on.